Corn thresher has many types. When the maize thresher is produced from the factory, it’s in good condition. As a responsible manufacturer and supplier, we enclose the safe operation regulations with the maize sheller.

Understand the corn sheller machine

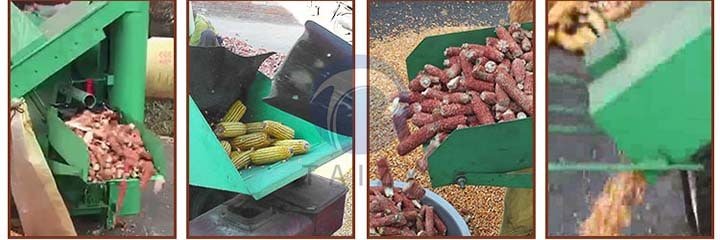

Firstly, you should understand what corn thresher is. For this machine, it only functions to thresh corns into corn seed and corn cob. Also, it can produce 6t per hour, a good assistant for the farms.

Things to attention

Generally speaking, when using the commercial corn sheller, we commonly divide it into three steps:

Before operation

- Carefully read this manual to understand the corn sheller structure, performance and operation of the machine.

- Test the machine before operation. The machine should be free from friction, abnormal sound and vibration.

- Send signal before starting the machine, in order to confirm nobody is around.

During operation

- Do not put your hand into the inlet, outlet and other dangerous running parts of the corn thresher.

- Prohibit to feed rocks, wood, metal and other hard objects into the machine, so as not to cause damage or injury to the machine.

- Forbid to stand at the rear of the outlet, so as not to be damaged by the object brought out by the high-speed rotating working parts.

After operation

- Confirm the work is completed, turn off the maize thresher.

- Remove all connections about the electric corn thresher and make sure no electrical connection.

- Check with everything, no problem and then leave.

Repair and Maintenance

Perform regular troubleshooting or cleaning checks, to avoid covering motor and transmission components with crop straw to avoid overheating and fire. Besides, the fasteners on the threshing drum, fan, bearing block, and other moving parts should be inspected regularly. If any damage, omission, or missing parts, deal with it in time.

All in all, keep the large-capacity corn thresher in good condition. If still any doubts, welcome to contact us at any time!