Fish feed pellet machine is one hot selling fish feed machine. It can process soybeans, rapeseed, rice bran, cornmeal, flour, and so on into dog food, fish feed, chicken, duck, rabbit feed. Also, it is used as aquatic feed pellets for fish, catfish, shrimp, crab, etc. This machine produces the animal feed with a certain puffed effect. From the above, you can know that it’s not only the floating fish food machine, also the pet food pellet machine. What’s more, this fish feed extruder machine can produce both the floating and sinking fish feed. You can achieve it by replacing the screw sleeve. This fish feed pelletizer can produce different particle shapes, with rich nutrition and reasonable structure. The diameter of the pellet can be 1-20mm based on the model dies. Welcome to contact us for more details!

Features of Fish Feed Pelletizer for Sale

- Simple and practical structure. The machine is exquisite in shape, simple in structure, easy to operate and maintain.

- Wide raw materials. Soybean meal, rapeseed, rice bran, fish meal, bone meal, corn meal, flour and so on.

- A variety of uses of finished products. Feed for dog, cat, fish, chicken, pig, duck, bird, shrimp, rabbits, etc.

- Multiple animals’ feed. This animal feed pellet machine can apply to different animals, suitable for kinds of customer groups, such as small medium-sized farms, middleman, individuals investing in new fields, research institutions and so on.

- High performance. That’s because it can eliminate most of the toxins contained in the material, facilitating the digestion and absorption of the animals and improving the digestion and utilization of nutrients.

- Long service life, durable and easy to maintain.

- High Accuracy. 100% molding is guaranteed, molds are optional by customers.

- Power can be electric motor and diesel engine.

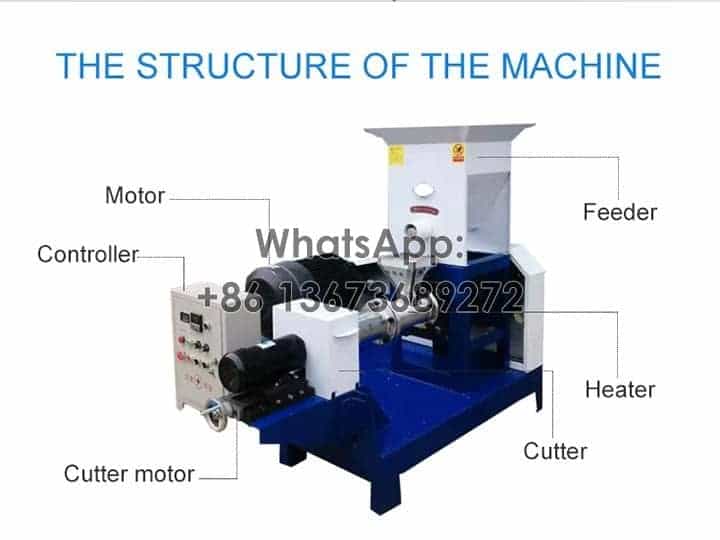

Main Structure of Floating Fish Feed Pellet Mill

This fish feed pellet machine is composed of feeder, extrusion device, power and transmission system, frame, electric control system, etc.

- Feeder. One screw is inside of the feeder, functioning to feed evenly.

- Extrusion device. It’s the core part of the fish food making machine. The corresponding combination is selected according to different uses, that is, different materials and different discharge methods.

- Models for discharging apertures. The discharge hole diameter series are φ1mm, φ1.5mm, φ2mm, φ3mm, φ3.5mm, φ4mm, φ5mm, φ6.8mm. Customers can choose from among them.

- Electric control system. This DGP series floating fish food extruder has different configurations according to the power of the main engine and the feeding methods. Totally three parts need power. One is the main engine, another one is the cutter, and the last one is feeding .

Technical Parameters of Fish Feed Pellet Machine

From the data, it’s easily found that the capacity increases along with the model changes. Also, the main power, cutter power, feed supply power differ. Obviously, we classify the model complying with the screw diameter, they’re corresponding. What’s more, the weight changes according to the models. So, when choosing the fish feed pellet making machine, tell us your all requirements, and we’ll recommend the most suitable one to you.

| Model | Capacity | Main power | Cutter power | Feed supply power | Screw diameter | Size | Weight |

| DGP-40 | 40-50kg/h | 7.5kW | 0.4kW | 0.4kW | 40mm | 1260*860*1250mm | 290kg |

| DGP-60 | 150kg/h | 15kW | 0.4kW | 0.4kW | 60mm | 1450*950*1430mm | 480kg |

| DGP-70 | 180-250kg/h | 18.5kW | 0.4kW | 0.4kW | 70mm | 1600*1400*1450mm | 600kg |

| DGP-80 | 300-350kg/h | 22kW | 0.4kW | 0.4kW | 80mm | 1850*1470*1500mm | 800kg |

| DGP-100 | 400-450kg/h | 37kW | 1.1kW | 1.5kW | 100mm | 2000*1600*1600mm | 1500kg |

| DGP-120 | 500-700kg/h | 55kW | 1.1kW | 2.2kW | 120mm | 2200*2010*1700mm | 1850kg |

Working Principle of Fish Feed Pelleting Machine

Put the raw materials into the feed box, and then push raw materials to the compression chamber by the extrusion screw (group), initially extruding and heating. After that, it is continuously heated by different degrees of extrusion until the material is discharged.

Operation Procedures of Fish Feed Pellet Machine

1. Mix the raw materials and mix them well.

2. Pour the mixed raw materials into the feed bin.

3. Turn on the cutter switch and adjust the cutter speed.

4. Adjust the distance between the cutter and the mold to control the size of the particles.

5. Turn on the host switch (green start button) to ensure the positive selection of the motor

6. Turn on the feeding switch and adjust the feeding speed. The final product pellets are obtained.

7. When the production is completed, turn off the main motor, turn off the cutter switch, and turn off the feed switch.

8. After stopping, remove the protective cover and keep the machine idling for one minute.

9. Take out the screw, clean it up, and clean up the mold for next use.

Successful Case

As a professional agricultural machine manufacturer and supplier, we received an inquiry from Niger. Niger customer asked about whether we were the cattle feed pellet manufacturers, this floating fish feed pellet machine for sale could be used as cattle feed pellet mill. Our sales machine Lena answered his doubts and recommended DGP-70 fish feed pellet machine to him. He compared with other companies and finally found our machines had good performance and super quality. Thus, he ordered from our company and agreed to deliver the machine by sea.

After a few months, he also asked about the pet food pellet machine for his friend and advised his friend to purchase from us due to our thoughtful services and professional knowledge. Through the long-term cooperation, now we’re good friends.